Designing in value and valuing design

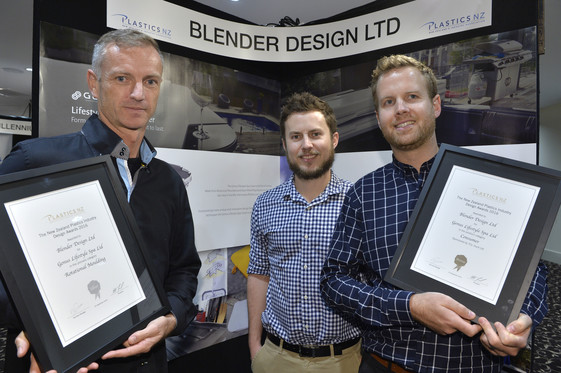

Tucked away in a quiet corner of the North Shore’s sprawling commercial zone, and a stone’s throw from Massey University’s Albany campus, is product design firm Blender. Founded in 2006 by product design specialists Oliver McDermott and Ben Thomsen, Blender have built up a strong portfolio of work and a reputation as insightful collaborators who add genuine value to the products they design for clients.

I met with McDermott, and started by asking him if clients have a good understanding of the value product designers bring to the development and manufacturing process.

“That understanding has improved over the last 10 years,” he says. “However there’s still a lot of work to be done. Generally, people know that design is valuable, but when it comes to spending the money on the upfront design work, gaining user insights...there are still a lot of people who need to get their head around that. They want to skip that phase and design what’s in their head.”

More clients, however, are becoming open to reframing the problem they think they are solving. “Maybe it’s because we’ve got better at convincing our clients that it’s necessary, or maybe they’re just getting more educated,” suggests McDermott. “We can step back and make sure we completely understand the market and user requirements. Then we can design a product that’s got a good market fit. We focus on the problem that the product solves, and who it solves it for, rather than just jumping straight into it.”

I ask McDermott what he thinks is improving design literacy within manufacturing businesses. He sees two sides to it. “The negative viewpoint on that would be fear; that they have to innovate or their competitors will overtake them. The other way of looking at it is that, with social media, and how connected the world is now, companies are being held accountable by their customers to make products that can solve their problems. It’s being driven by that need to listen.”

He suggests that the product development dynamic has changed for many businesses. “Gone are the days when you can make a crappy product and give it to the sales team to sell, right? Now the sales and marketing team need to come up with unmet problems, and then get the business to design a product to solve that problem. It’s quite simple really.”